Characteristic/Characteristic

◆ Small footprint, no air consumption; rapid bar change speed.

◆ Can transport flat square material, triangular or four corners and other special-shaped materials, as well as Φ2 or so small materials, cost-effective;

◆ Using pulse data control, the cutting end of the first piece of material can be stably controlled within 0.20mm;

◆ PLC plus servo, touch screen control, data operation, easy to use;

◆ Electrical and mechanical faults can be diagnosed by themselves, easy and fast maintenance;

◆ The tool life can be managed, the materials and production capacity can be counted, which is convenient for quality control and operation management.

| Item | LSCT/N-08 | LSCT/N-12 | LSCT/N-16 | LSCT/N-20 | |

| Processing capacity | 棒料加工MAXIMUM直径 | Φ8mm | Φ12mm | Φ15mm | Φ20mm |

| Bar machining maximum diameter | |||||

| 棒料加工MINIMUM直径 | Φ2.0mm | Φ4mm | Φ5mm | Φ6mm | |

| Bar machining minimum diameter | |||||

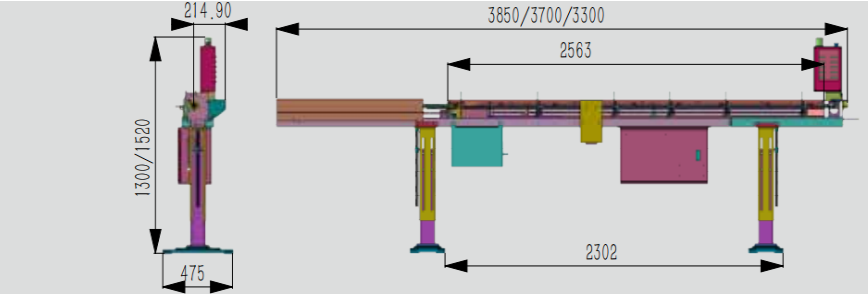

| 棒料加工长度 | 2500mm-3000mm | ||||

| Length of the bar machining | |||||

| 料仓活动范围 | Φ9mm | Φ13.5mm | Φ16.5mm | Φ23mm | |

| The silos activities range | |||||

| Other | 棒材容量 /Material capacity | Φ8×35pcss | Φ12×23pcs | Φ15×18pcs | Φ20×14pcs |

| 总电气容量/Required eiectric power | 0.61kw | 0.46kw | |||

| 机床重量 / Mass of machine | About 165kg | About 155kg | |||

| 功率 / Power | 50-60Hz | ||||

Recommend Products

Get A Free Quote

ASK YOUR QUESTIONS

Ready to start a project?

Let’s talk about it

Let’s talk about it

Your satisfaction is our biggest pursuit, if you have any questions and want to know, please fill in the next form to send your feedback or suggestions to us, we will reply you as soon as possible.

- WhatsAppWhatsApp:86-13631284694

- Call UsCall Us:86-13959766267/86-13631284694